TRAINING

We can provide specialized training to your operators, helping to familiarize them with the navigation and operation of your automation system. If we’re expanding your existing system and your operators have some experience with your current controls, we can gear the training to focus on specific new and enhanced system functionality. If we are introducing something entirely new, our team can train your operators step by step, covering every key component and function to have optimal operation of the Process/Machines.

Either way, the purpose of this training is to get your operators familiar, comfortable and productive with your control system interface and able to run your process while producing high-quality, repeatable results. Also, the enhancement of the operator skill makes better availability of the Process/Machine thus increase your productivity directly.

TRAINING ON NEW SYSTEMS

It is important that the members of your team who are responsible for utilizing your new system on a regular basis are competently trained and fully prepared for the implementation of your new system. Our team also understands there are a variety of options for operator training.

Our offerings range from thorough, comprehensive simulations in a controlled environment to on-site, in-person training on the live system. Regardless of your needs, we focus on mitigating your concerns, addressing potential knowledge deficiencies, and adequately preparing your team to begin production. We enjoy working with and training operators because their insights into the processes are invaluable.

They can help drive more efficiency out of your system which is why we are passionate about helping them become well-trained to do so. This helps the organization to implement Time Based Maintenance Activities for each process/Machines with Proactive Maintenance care.

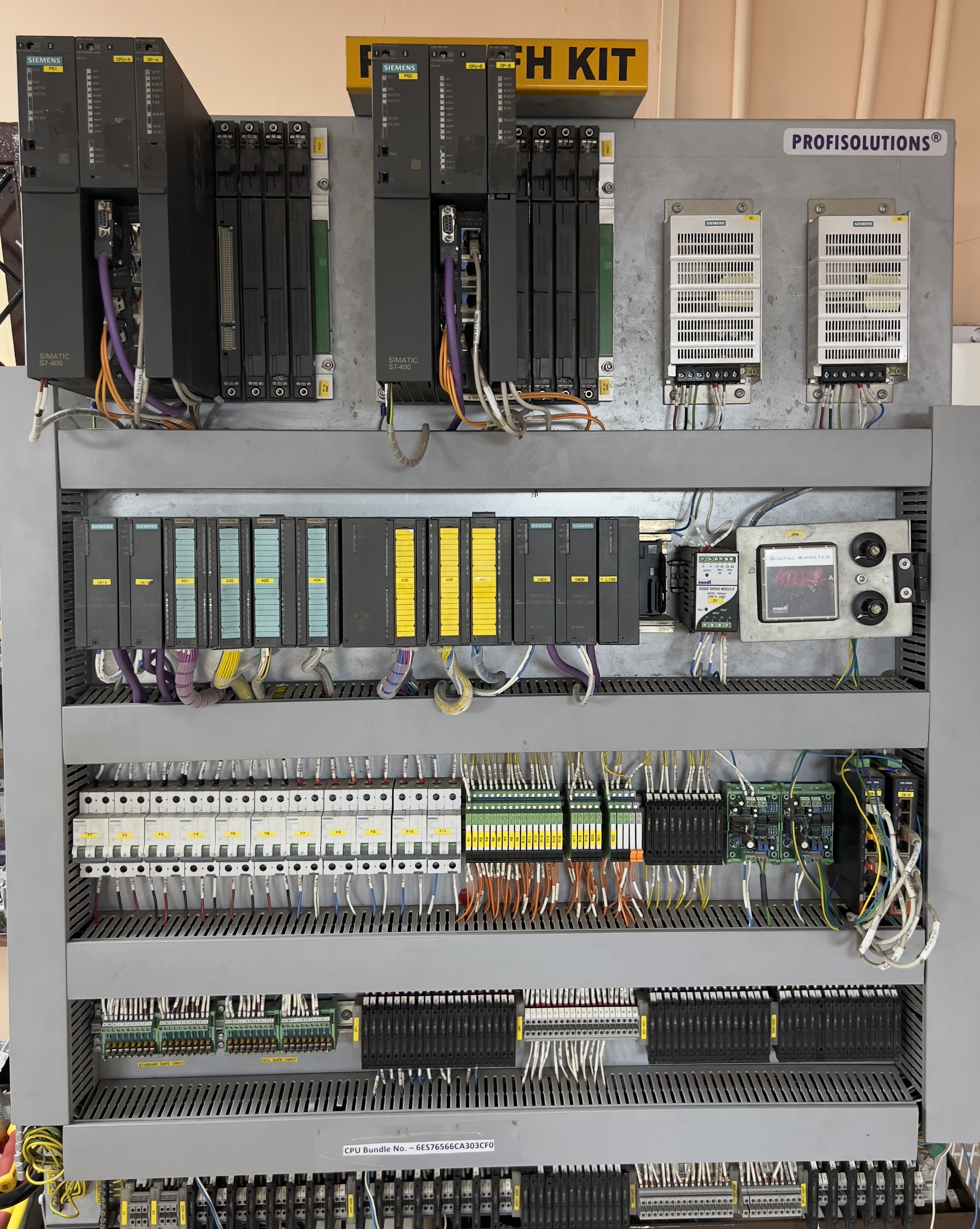

PROCESS SIMULATION

Depending on the needs of your team, we can provide low-, medium-, or high-fidelity simulations that closely resemble your real process system. Your team can train in real-world-like process conditions in a controlled environment. Process upsets and fault conditions can be simulated without wasting valuable ingredients or damaging process equipment.

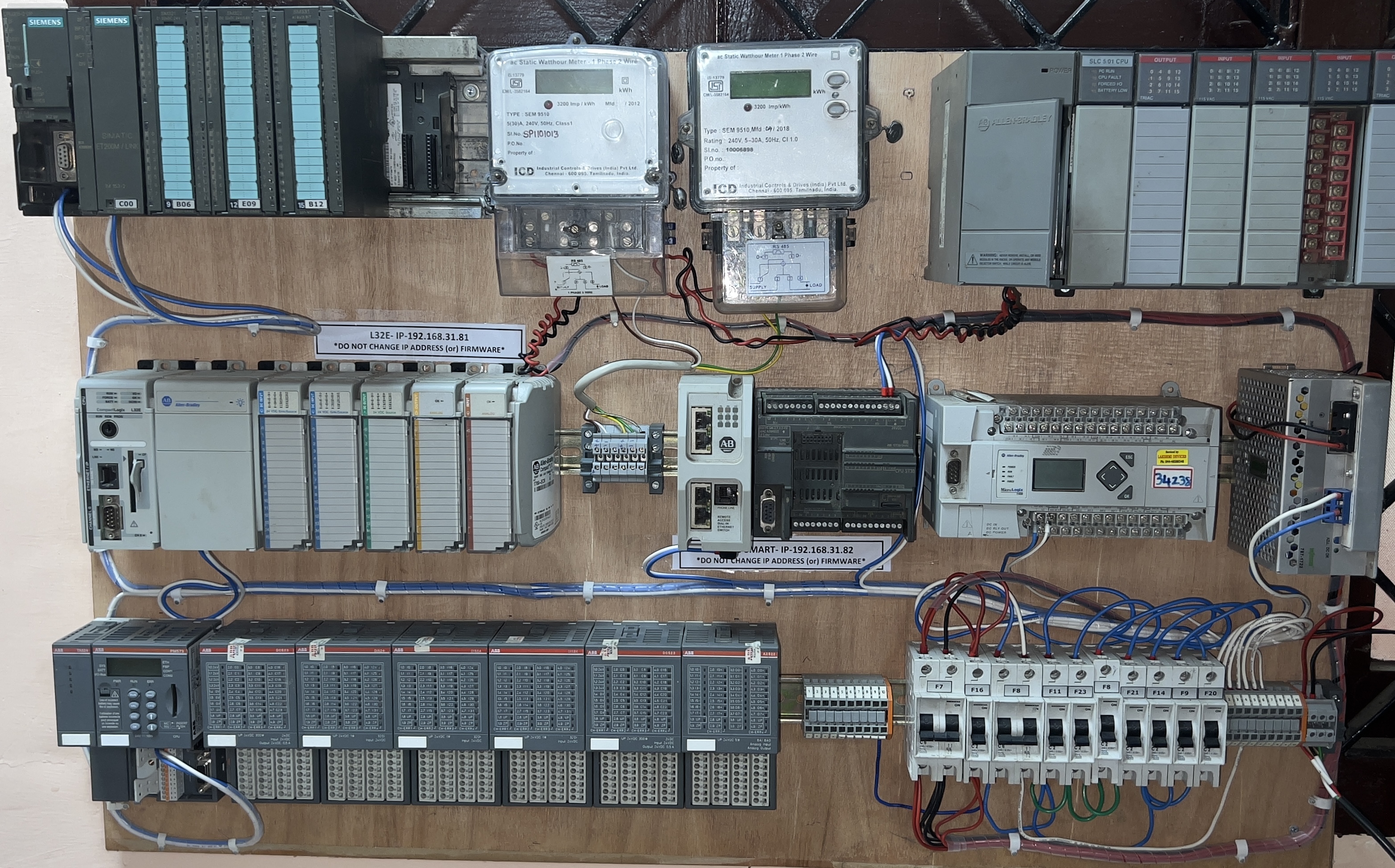

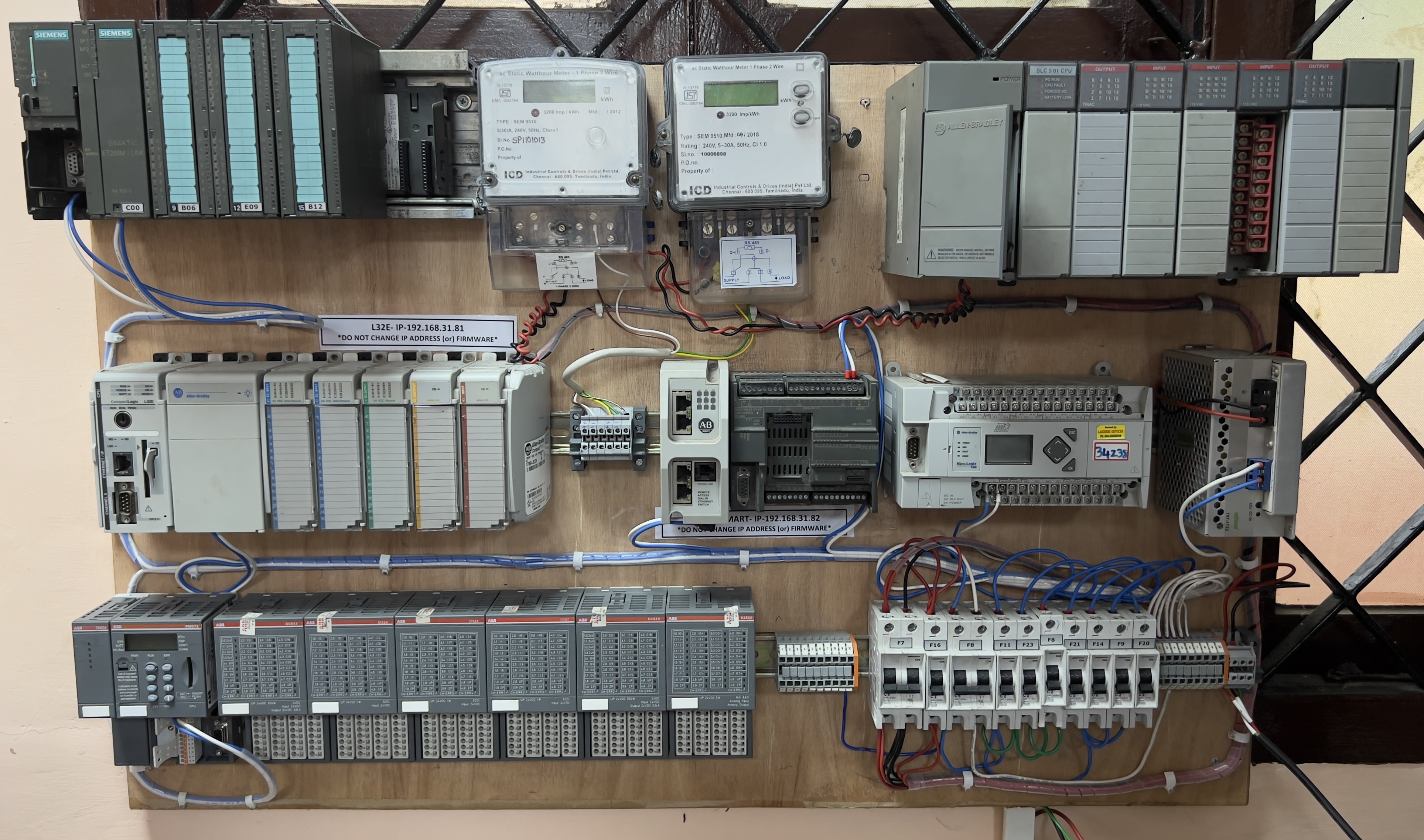

IN-PERSON TRAINING

After your system has been assembled and is ready to be implemented in your environment, our team of automation specialists can work with your operators in hands-on training including a comprehensive review of everything they will find in your new control system interface. These hands-on training sessions can be fully customized to the proficiency level of your operators; either offering a review of the system and its processes or drilling down to every aspects of control, monitoring and reporting.

ONGOING SUPPORT

As time progresses, your control systems evolve, and as new team members are brought on board, training needs might change. At your request, our team stands ready to assist your operators well after implementation, helping provide ongoing support and individualized care.